Just How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes represents a substantial improvement in quality control methodologies. By offering real-time, accurate dimensions of Fibre diameters, this innovation attends to the crucial requirement for consistency in production standards.

Significance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is vital in the field of optical Fibre technology, as it directly affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Precision in measuring Fibre Diameter makes certain that the optical homes are kept within specified resistances, which is essential for optimum signal stability.

Variations in Fibre Diameter can bring about raised losses because of scattering and modal dispersion, impacting the top quality of information transmission. In high-speed communication systems, such inconsistencies can result in significant destruction of signal top quality, causing data mistakes and minimized performance. Furthermore, consistent Fibre Diameter is necessary for compatibility with ports and splicing technologies, which are integral components of Fibre optic networks.

Quality control procedures in Fibre manufacturing greatly count on exact Diameter dimensions to make certain compliance with sector requirements. By applying robust dimension methods, makers can improve item reliability, minimize waste, and boost overall system efficiency. Therefore, the value of Fibre Diameter dimension can not be overstated, as it serves as a foundation in the innovation of optical Fibre innovation and its applications in modern-day communication networks.

Exactly How the Analyser Functions

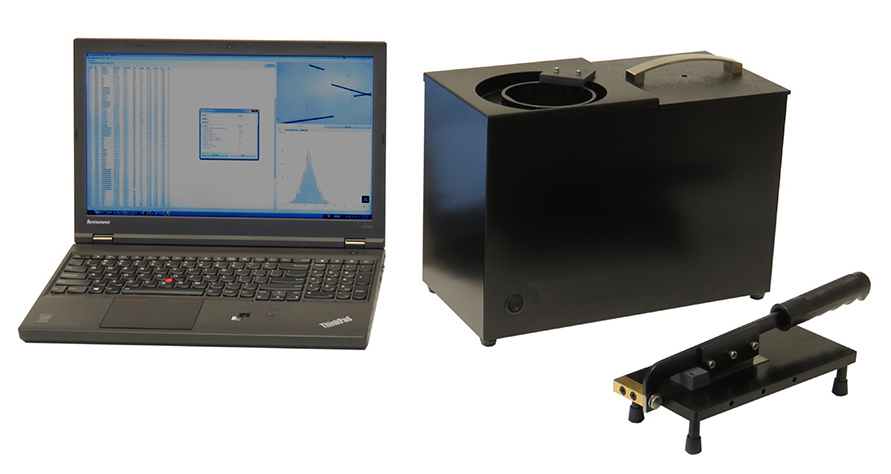

The effective measurement of Fibre Diameter counts on advanced analytical methods that make sure accuracy and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed photo processing algorithms to properly assess the Diameter of fibers as they are created

Initially, a laser beam of light is directed at the moving Fibre, developing a cross-sectional darkness. The analyser captures this shadow using high-resolution electronic cameras placed tactically along the assembly line. The caught pictures are then processed in real-time to establish the Fibre's Diameter with remarkable accuracy.

The system makes use of innovative algorithms that make up different variables, consisting of variations in light intensity and ecological conditions, to enhance measurement integrity. It can discover minute adjustments in Diameter, such as changes that might occur during the manufacturing process.

Moreover, the analyser is qualified of dealing with several fibers concurrently, increasing throughput without endangering precision. By supplying instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays a critical function in maintaining rigorous top quality control requirements, making certain that the final item meets industry requirements and customer needs.

Advantages of Real-Time Surveillance

While typical techniques of keeping an eye on Fibre Diameter typically entail time-consuming post-production checks, real-time monitoring substantially improves the performance and quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive approach allows producers to determine discrepancies in Fibre Diameter as they occur, instead of waiting up until production is total to analyze top quality

By continuously determining the Diameter during manufacturing, manufacturers can make certain that the fibers fulfill stringent requirements, bring about decreased irregularity and boosted consistency. Real-time surveillance also allows instant corrective activities to be taken, reducing waste and protecting against malfunctioning fibres from getting in the supply chain.

Moreover, this innovation assists in boosted data collection and analysis, providing understandings into production patterns and possible areas for enhancement. Such data-driven decision-making encourages manufacturers to enhance procedures and keep high standards of high quality control.

Additionally, real-time surveillance fosters a culture of constant enhancement within the manufacturing setting. Employees are more involved when they can see the impact of their work in real-time, causing enhanced accountability and a commitment to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing equates to exceptional item high quality and boosted client complete satisfaction.

Impact on Production Efficiency

Executing optical Fibre Diameter analysers substantially improves manufacturing effectiveness by enhancing the manufacturing process. These gadgets help with constant tracking of Fibre Diameter, permitting suppliers to identify discrepancies in real-time. By identifying inconsistencies promptly, production lines can be readjusted rapidly, minimizing downtime and reducing the probability of creating defective products.

In addition, the website here assimilation of these analysers into the production operations allows better source allowance. With exact Diameter measurements, drivers can enhance material use, making certain that resources are not wasted on mistaken fibres. This accuracy likewise adds to much less ditch and rework, inevitably reducing production expenses.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated assessments, which are commonly time-consuming and susceptible to human mistake. Consequently, staff members can concentrate on even more calculated tasks, improving overall efficiency.

Moreover, the data created from these analysers can inform procedure renovations and help with far better decision-making. By assessing trends in Fibre Diameter variations, makers can implement positive actions to enhance production strategies and maintain consistent quality. In summary, optical Fibre Diameter analysers play a vital duty in increasing production performance, leading to better result and increased success.

Instance Studies and Success Stories

Across numerous industries, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One noticeable example is a leading telecommunications company that dealt with obstacles with inconsistent Fibre diameters, causing raised rejection prices. By integrating an optical Fibre Diameter analyser, the firm achieved real-time tracking of Fibre dimensions, leading to a 30% reduction in problems and considerable expense savings.

In addition, a research study institution concentrating on advanced products used optical Fibre Diameter analysers to fine-tune their experimental procedures. The analyser's capability to give in-depth understandings into Fibre consistency made it possible for the development of cutting-edge materials with better performance attributes.

These success tales highlight the important duty of optical Fibre Diameter analysers in boosting quality control, enhancing manufacturing effectiveness, and driving technology across varied sectors.

Final Thought

Finally, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality assurance within Fibre production. By supplying precise, real-time measurements and facilitating instant rehabilitative actions, this innovation significantly decreases irregularity and decreases waste. The implementation of such advanced tools promotes a society of continual improvement and functional efficiency, eventually making sure conformity additional hints with sector criteria and maintaining competitiveness. As demonstrated with different situation researches, the analyser verifies essential for achieving remarkable item top quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for strict quality control, making sure that the produced fibers satisfied exacting market standards.In final thought, the Optical Fibre Diameter Analyser plays a crucial role in boosting quality control within Fibre production.